Quality Mold Starts from Excellent Custom Mold Design

At YWX mold design manufacturers, our experienced designers play a crucial role in ensuring the quality of our tools. With years of expertise, the YWX mold design company collaborates closely with customers to develop well-designed molds that are easy to maintain and cost-effective to produce.

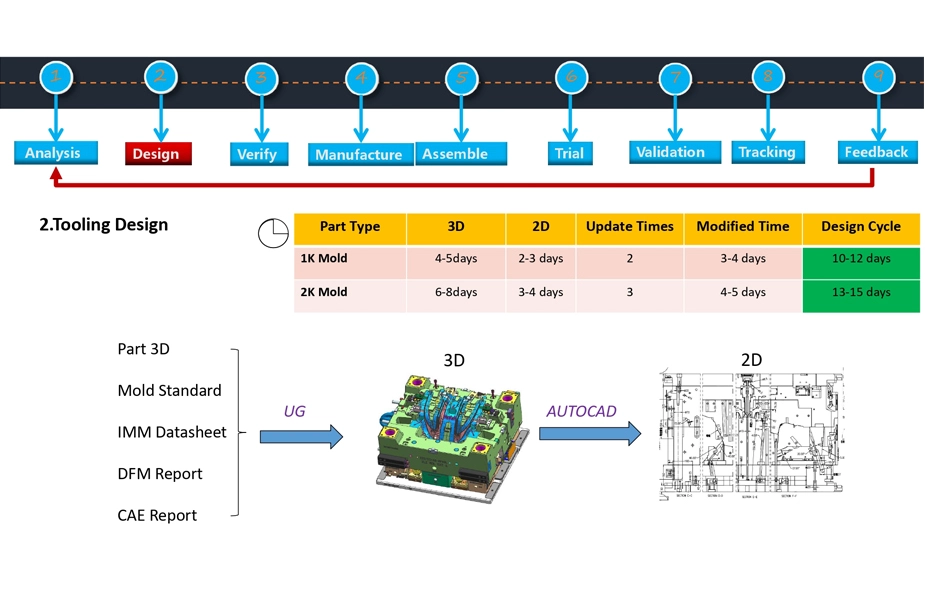

Our skilled in-house design team, with over 15 years of experience, offers a comprehensive design package. Our mold design services include feasibility studies, design recommendations, filling simulation, Moldflow analysis, and 2D & 3D tool design using CAD, Unigraphics, and other software.

If needed, our mold design designers can be involved in the early stages of a project to support part development and enable a tool-specific design, saving you time and costs.

Choose the YWX mold design manufacturer for excellent custom mold design services and engineering expertise.

Mold design and engineering play a crucial role in the production of high-quality plastic parts. Our expert team at YWX mold design company provides comprehensive mold design and engineering services, including feasibility studies, filling simulation, and 2D & 3D tool design. We specialize in 2K plastic mold design and 2K spin stack mold design, enabling the production of complex plastic parts with multiple materials or colors. Our innovative design approach ensures precise alignment and seamless integration of different components, resulting in efficient manufacturing processes and superior product quality. Choose YWX mold design manufacturer for exceptional mold design and engineering expertise.

Proper parting line design: The selection of the parting line is crucial for mold design as it affects the mold's complexity, part quality, and production efficiency.

Gate design: The gate location and size impact the flow of molten plastic into the mold cavity, affecting part quality and cycle time.

Cooling system design: Effective cooling is essential for maintaining consistent part dimensions, minimizing cycle time, and preventing defects.

Venting design: Proper venting ensures the escape of air and gases during the molding process, preventing defects like burns or voids.

Ejection system design: A well-designed ejection system ensures smooth part removal from the mold without damage or deformation.

The process of mold design and engineering involves several key steps to ensure the successful production of high-quality molds and reliable mold services. These steps typically include:

Product Design: The process begins with the design of the desired plastic part, taking into consideration its functionality, aesthetics, and manufacturability.

Mold Conceptualization: Based on the product design, engineers conceptualize the mold, considering factors such as parting line, gate locations, cooling systems, and ejection mechanisms.

Mold Design: Using specialized software, engineers create detailed 2D and 3D designs of the mold, incorporating all necessary features and components.

Mold Manufacturing: Once the design is finalized, the mold is manufactured using various techniques such as CNC machining, EDM (electrical discharge machining), or additive manufacturing.

Testing and Refinement: The newly manufactured mold is tested to ensure it meets the desired specifications and functionality. Any necessary adjustments or refinements are made at this stage.

Production: With a validated mold, it is ready for mass production. The mold is installed in an injection molding machine, and the desired plastic parts are produced.

Throughout the entire process, collaboration between mold designers, engineers, and mold design manufacturers is crucial to ensure the mold meets all requirements and specifications.

The time required for mold design varies depending on factors such as part complexity, design specifications, and the experience of the design team. On average, designing a 1K mold can take around 10-12 days, while designing a 2K mold may take around 13-15 days. These timelines include both the 3D design phase and the 2D design phase, as well as any necessary updates or modifications. It's important to note that these timelines for mold design are estimates and can vary based on specific project requirements.

Email Us Directly

marketing@ywxmolding.com