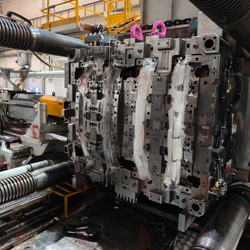

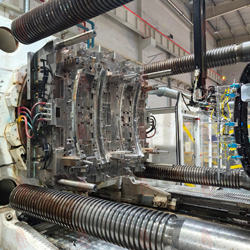

On January 23, 2025, we are proud to announce that the Headlight 2K Rotated Mold has completed its transfer and has smoothly undergone trial production on the Valeo factory's 1900T Rotation Plate 2K injection machine. This milestone marks another significant breakthrough in our field of headlight mold manufacturing.

Product Size: 94X1138X223 mm

Product Material: PC Black + PC Clear

Product Weight: 400g (Black) + 452g (Clear)

Type: 1900T Rotation Plate 2K Injection Machine

Hot Runner: Moldmasters 16 Points Needle Valve

Tool Size: 190016501195 mm

Tool Weight: 23000 KG

Cavity Configuration: 1+1+1+1

Cycle Time: 68 seconds

Kick-Off Date: July 2024

In just six months, from project initiation to mold transfer to the customer’s factory and successful trial production, we have demonstrated tight collaboration among all departments and team members. By focusing on the needs of our headlight customers and continuously enhancing the quality standards of these components by custom prototyping, YWX Company is better positioned to meet the professional requirements of our clients.

This focus on niche areas allows YWX Company not only to improve product quality but also to provide more specialized services to our customers. The smaller team size facilitates the implementation of a flat management structure, significantly enhancing decision-making efficiency and execution capability.

Flat management helps establish an efficient core team covering key areas such as design, processing, assembly, and polishing, thereby enhancing overall management levels. Our stringent quality management requirements drive the establishment of comprehensive project management processes, ensuring standardized management across design, processing, assembly, and testing stages.

Through rigorous project management, we ensure product quality and enhance customer satisfaction. The preliminary feasibility analysis, based on our years of experience in headlight mold manufacturing, successfully mitigated multiple potential risks and issues, providing strong support for the smooth progression of the project.

We would like to express our gratitude to every team member for their hard work and dedication. It is your efforts that enable us to continually innovate and break new ground in the field of headlight mold manufacturing. Let’s continue to move forward together and create even more remarkable achievements!