Our mold drawing design service provides complete and effective design input, ensuring the quality of mold drawing and every detail. YWX, the plastic mold design company uses product data, customer sample outlines, injection molding machine data, DFM, and CAE reports to draw mold data using UG and AUTOCAD software. Our experienced YWX team communicates cheerfully with customers and coordinates smoothly with internal departments. YWX plastic mold design company has solid executive power, a high sense of responsibility, and is worthy of trust. Our team is familiar with international standards and the design of molding components, including DME, Hasco, Misumi, Strack Normalien, Progressive, PCS, Meusburger, and Cumsa. We can also meet any specific plastic prototype design standards required by our customers.

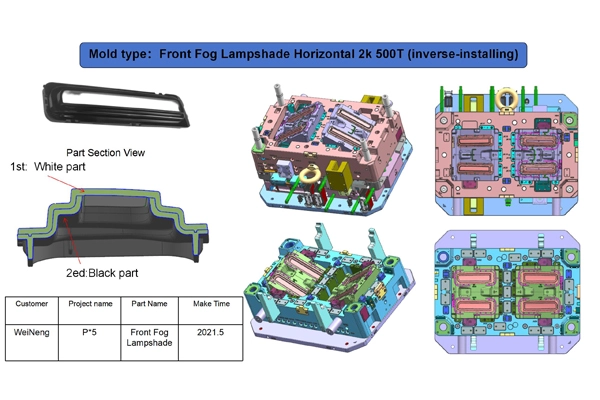

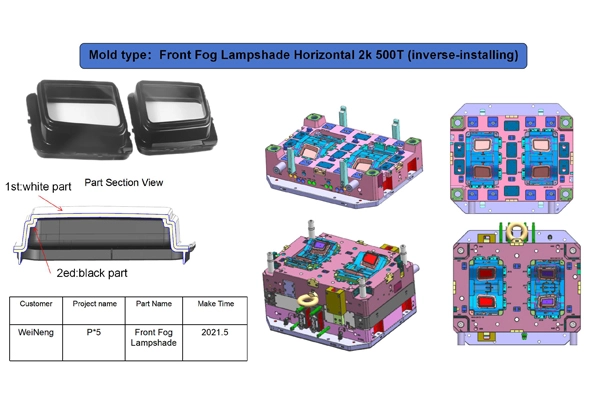

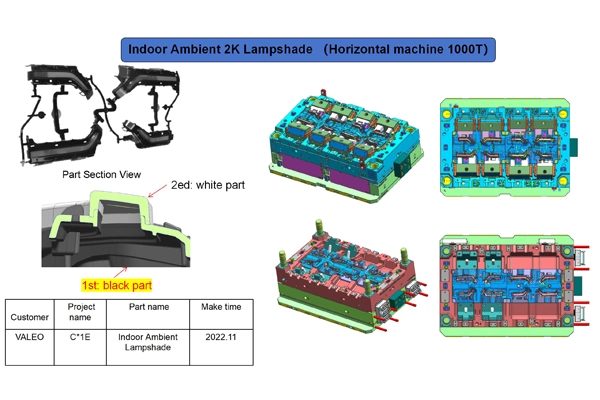

Headlight two-color lampshade technology requires a specific molding sequence to achieve the desired color layout. Traditionally, the black part is molded first, followed by the white part which can cause color mixing at the junction. To avoid this issue, the white parts must be molded first, and then the black parts. This change in sequence requires corresponding modifications to the mold structure.

The modifications include fixing the white parts on the front mold instead of the rear mold, using a flip-chip mold to feed plastic from the rear mold, and adjusting the ejection power of the rear mold. These changes pose challenges in mold design and production.

To ensure stable fixation of white parts on the front mold, corresponding structures need to be added. The length of the hot nozzle for feeding plastic from the rear mold is longer, making temperature control accuracy and hot runner requirements more demanding. Additionally, ejecting and injecting from the rear mold makes it difficult to maintain design and processing accuracy.

1. Draft: Adding draft angles to the mold design allows for easy ejection of the molded part from the mold cavity.

2. Radii: Incorporating rounded corners and edges helps to prevent stress concentrations and improve the strength and durability of the molded part.

3. Wall Thickness: Designing uniform wall thickness throughout the part ensures proper flow of molten plastic during the injection molding process and avoids issues like sink marks or warping.

4. Product Design: Creating a detailed product design is essential before proceeding with mold design. This plastic mold design considers functional requirements, aesthetics, and any specific features or details required.

5. Mold Manufacturing: Once the product design is finalized, the mold is manufactured to fit the design. This involves precise machining and assembly of mold components.

6. Injection Molding Technologies: Various techniques like co-injection molding (using multiple materials), gas-assisted injection molding (for hollow parts), and multicomponent injection molding (combining different materials or colors) can be employed to achieve desired functionality and aesthetics.

By considering these aspects, plastic mold design ensures successful and efficient production of high-quality molded parts.

Improvement suggestions for the mentioned issues in the 2K plastic mold design:

1. Product bright line: To address cracking during the coating process, improvements can be made in preloading amount, processing technology, and polishing technique. Ensuring proper preloading, optimizing processing parameters, and using appropriate polishing techniques can help minimize cracking at the junction of black and white parts.

2. Black part trap: To prevent air trapping during molding of the black part, mold flow analysis can be conducted to optimize gate settings, wall thickness analysis, and exhaust settings. This plastic tool design will help ensure proper venting and minimize the risk of air trapping in the mold.

3. Mixed color: It is important to focus on processing accuracy and process control to maintain colour consistency during two-shot moulding. Ensuring precise execution of the two-shot molding process and implementing strict quality control measures can help minimize color variations between different parts of the headlight lampshade.

4. Indentation/iron powder: To avoid issues like indentation or iron powder, it is crucial to establish proper fit clearance standards, maintain machining accuracy, and conduct thorough measurements and inspections after mold fit is completed. Additionally, verifying mold hot fit can help identify and address potential issues before production.

By implementing these improvements, the quality and performance of the plastic mold design can be enhanced, leading to better overall results in the production of headlight lampshades.