Automotive prototyping involves creating preliminary versions of vehicles or components to test and refine designs before mass production. This process includes concept development, physical and functional prototyping, and rigorous testing for performance, safety, and reliability. By identifying and resolving issues early, automotive prototyping ensures cost efficiency, innovation, and market readiness, ultimately leading to high-quality, reliable, and compliant final products.

Benefits of Plastic Injection Molding in Automotive Manufacturing

High Precision Production of Complex Parts

Injection molding can produce complex and precise plastic components with good reproducibility.

Highly Durable

Modern lightweight thermoplastics are more durable in harsh environments than metal parts.

Lightweight and Various Color Options

Using injection-molded plastic parts can reduce weight and achieve a variety of colors and transparencies.

Enhanced Flexibility

Provides design flexibility, suitable for components with various geometries.

Better Surface Finishes

Injection molding can achieve smooth, flawless surface finishes and offers various surface effects.

Various Material Choices

A wide range of flexible, rigid, and rubber plastics can be used to meet different applications.

High Efficiency and Quick Production

The injection molding process is fast, with short cycles and high efficiency.

Cost Reduction

The production cost of injection-molded plastic parts is lower than that of metal parts, and it is easy to mass-produce.

High Precision and Short Production Time

High-precision plastic parts can be produced in a short time, meeting strict tolerance requirements.

Consistent Production Quality

Automotive Lighting Systems

Benefits:

Lightweight: Plastic parts are lighter than metal, helping to improve fuel efficiency.

Design Flexibility: Can achieve complex shapes and various colors, enhancing the vehicle's appearance.

Durability: High-quality plastics are impact-resistant and UV-resistant, extending their lifespan.

Thermal Systems

Benefits:

Thermal Stability: Suitable for high-temperature environments, ensuring the system operates normally.

Insulation Properties: Plastic materials provide good electrical insulation, enhancing safety.

Cost-Effectiveness: Injection molding reduces production costs and increases manufacturing efficiency.

Interior Systems

Benefits:

Diverse Designs: Can achieve various textures and colors, improving interior aesthetics.

Comfort: Lightweight plastic materials enhance comfort and reduce cabin noise.

Durability: Strong wear and stain resistance, making them easy to clean and maintain.

Exterior Systems

Benefits:

Corrosion Resistance: Plastic parts are less prone to rust, adapting to various weather conditions.

Aesthetic Appeal: Offers various surface treatment options, enhancing visual attractiveness.

Safety: Provides better energy absorption during collisions, protecting occupants.

YWX provides high-quality injection molds globally since 2014. We're known for cutting-edge technology, strict quality standards, and efficient project management. We've established strong partnerships with renowned automotive OEMs and Tire-1 companies. Our team consists of over 80 technical personnel and we're ISO 9001 certified. We can produce molds up to 30 tons using 40000rpm CNC and 5-axis CNC. Our expertise lies in automotive lighting and thermal & interior & exterior systems. We offer our support as your dependable international partner.

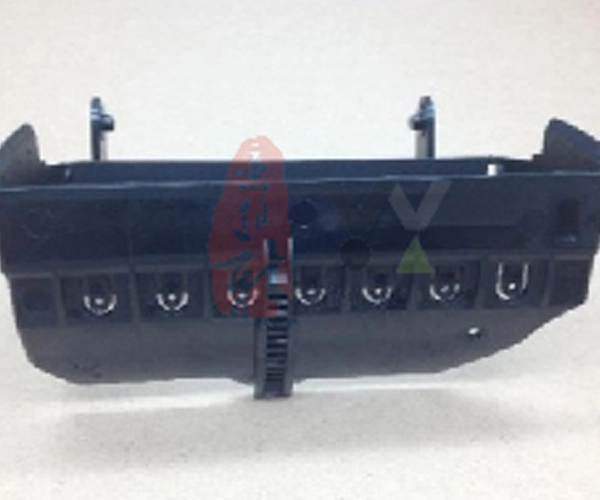

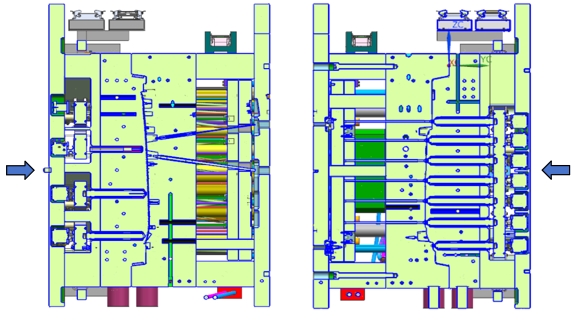

Product Information :

Product Name : Door Trim Panel

Product Size :920*420*110

Product Material :PP+TPE

Product Weight :1398.5g

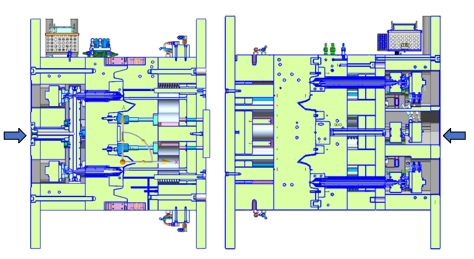

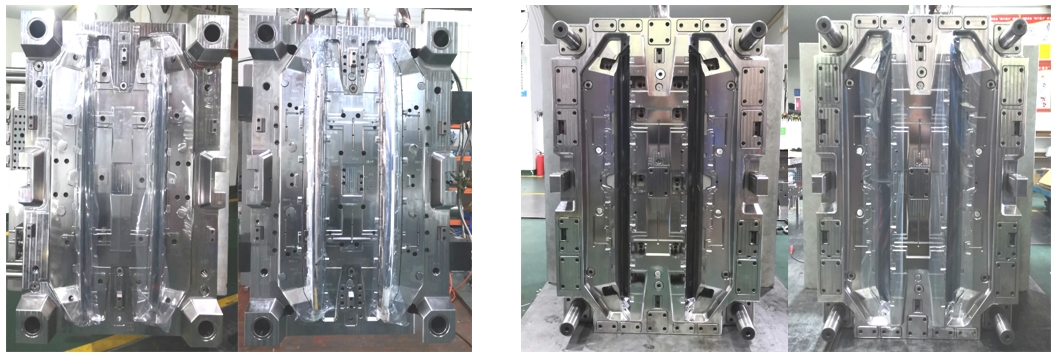

Tools Information :

Type:1800T Opposite Spin Stack 2K Mold

Hot Runner:8+19 points Valve Nozzle

Tool size:1700*1530*940*2

Tool Weight :13899KG*2

Cavity:1+1

Cycle time :68S

Make time :2022.12

Type:

1.Opposite Spin Stack 2K Mold

2.Separate

3.Same Color Different Materials

4.Soft Plastic Covering Hard Plastic

5.Standard Mold

Challenges:

Achieving seamless flow across a large surface of soft rubber over hard plastic while preventing air entrapment and avoiding flashing defects.

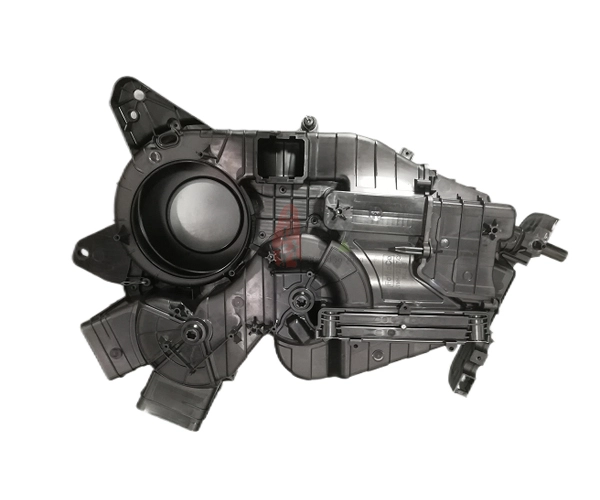

Product Information :

Product Name :Door Trim Panel

Product Size :860*330*133

Product Material :PP+TPE

Product Weight :1455.6g

Tools Information :

Type:1800T Opposite Spin Stack 2K Mold

Hot Runner:8+19 points Valve Nozzle

Tool size:1700*1530*920*2

Tool Weight :13784KG*2

Cavity:1+1

Cycle time :68S

Make time :2022.12

Type:

1.Opposite Spin Stack 2K Mold

2.Separate

3.Same Color Different Materials

4.Soft Plastic Covering Hard Plastic

5.Standard Mold

Challenges:

Achieving seamless flow across a large surface of soft rubber over hard plastic while preventing air entrapment and avoiding flashing defects.

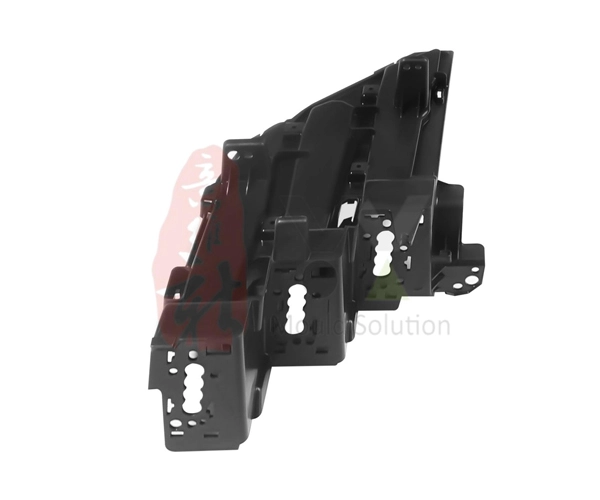

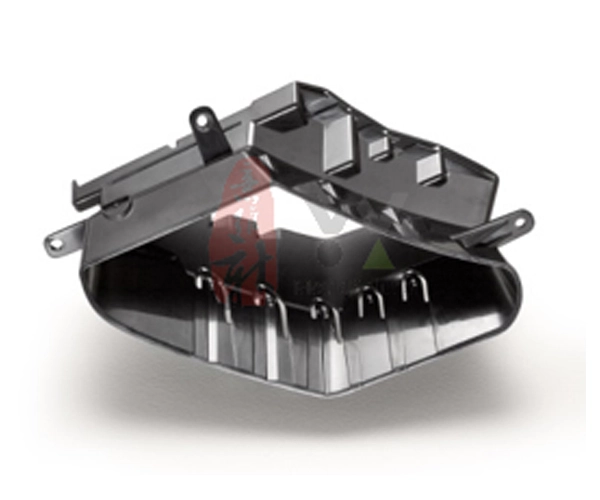

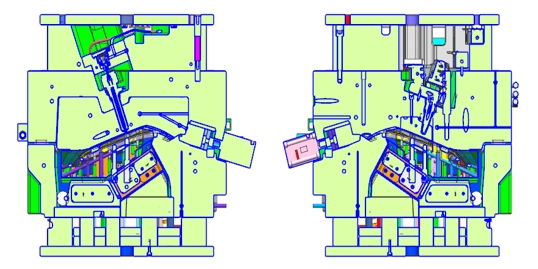

Product Information :

Product Name : 3K RCL lampshade

Product Size :338*143*152

Product Material :PMMA Black+Clear+ Red

Product Weight :313.8g

Tools Information :

Type:1400T Vertical Rotation 3K Machine

Hot Runner:Master 9 points Valve Nozzle

Tool Size:1150*700*950(Z)*2

Tool Weight:4239KG*2

Cavity:1+1

Cycle time :45S

Make time: 2019.06

Type:

- Vertical Rotation

- Separate

- 3 Different Colors

- Standard

Challenges:

- Mirror Sealing: Achieving effective sealing for reflective surfaces.

- High Product Drop: Managing impact during handling and transportation.

- Internal Voids: Preventing air pockets within the molded parts.

- Defect Avoidance: Mitigating issues such as:

- Pressure Marks

- Iron Powder Contamination

- Bright Lines

- Cracking

- Deformation

Addressing these challenges requires meticulous attention to the injection molding process and stringent quality control measures to ensure the final product meets both aesthetic and functional standards.

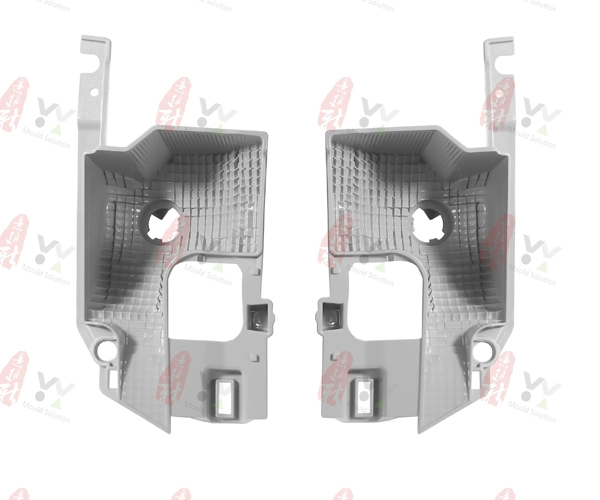

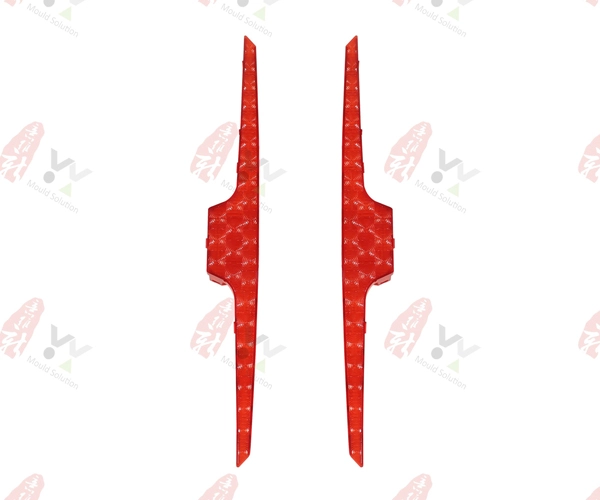

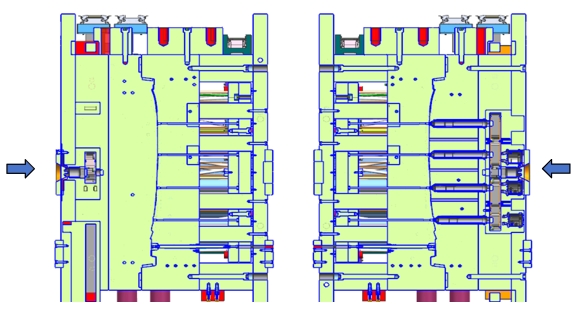

Product Information :

Product Name : HL LENS

Product Size :983*98*138

Product Material :PC black+PC clear

Product Weight :933.7g

Tools Information :

Type:1800T Opposite Spin Stack 2K Mold

Hot runner:Masters 8 points Valve Nozzle

Tool Size :1200*1200*1110*2

Tool Weight:8980KG*2

Cavity:1+1

Cycle time :48S

Make Time:2022.12

Type:

- Opposite Injection

- Central Rotation

- Separate

- Same Material with Different Colors

- Reversed Mold

Challenges:

- Appearance Parts: Ensuring high aesthetic quality in visible components.

- Mirror Sealing: Achieving effective sealing for reflective surfaces.

- Defect Avoidance: Preventing issues such as:

- Pressure Marks

- Iron Powder Contamination

- Bright Lines

- Cracking

- Deformation

These challenges require precise control over the injection molding process and careful material selection to ensure product quality and performance.