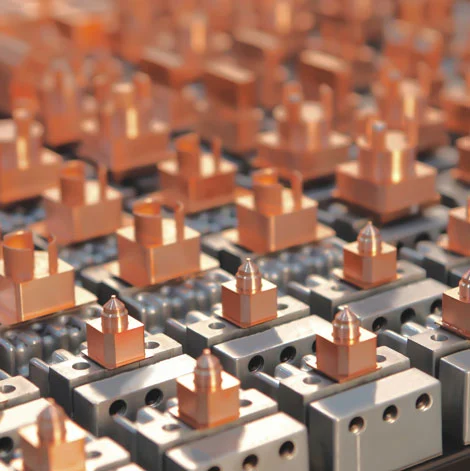

We have equipped our facility with state-of-the-art processing and production equipment. As a metal injection molding manufacturer, we strictly adhere to the quality control processes outlined in ISO9001 to ensure that our products meet the highest quality standards.

Our world-class production and testing equipment provide a strong guarantee for the precision of your products. We utilize precise measuring equipment to ensure accuracy and consistency throughout the manufacturing process.

We prioritize quality at every stage of production. That's why we conduct 100% inspection for the entire process, from incoming materials to the shipment of products. This comprehensive inspection ensures that every product leaving our facility meets our stringent quality requirements.

At YWX, we understand the importance of quality control in providing optimal silicone molding services performance. We implement rigorous quality control measures to ensure that every product meets our high standards of precision, reliability, and overall quality.

In a recent case study, our meticulous quality control measures in molding services led to exceptional success. By implementing strict inspection processes, utilizing precise measuring equipment, and adhering to ISO9001 standards, we consistently delivered high-quality products. Our commitment to quality control played a pivotal role in achieving customer satisfaction, boosting efficiency, and driving overall success in the molding service industry.